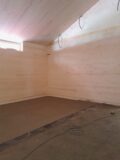

Floor

Our rammed earth floors made from 100% earth combine precision craftsmanship with responsible use of resources. The heterogeneous, natural surface with fine micro-cracks gives the floor a timeless aesthetic despite its hardness. Compacted in layers and carefully worked, the result is a robust surface. The clay floor can be customized with different clay mixtures and finishes such as dimamant sanding. Impregnated with wax and polished, rammed earth floors are hard-wearing and easy to maintain.

Due to its high specific weight, rammed earth can store heat and release it back into the room with a time delay – it therefore has a balancing effect. This effect could be controlled by integrated heating pipes.

Our rammed earth floors are mainly determined by the geological composition of the soil used. We mainly use excavated material from the excavation pit or the region for production. The originality of our work steps requires a high level of craftsmanship – it is not for nothing that the production of a good rammed earth floor is referred to as the supreme discipline.

Various insulation systems can be used under the rammed earth floor. It is important to ensure that this insulation layer can withstand the necessary compaction pressure. The use of impact sound insulation is possible to a limited extent, but must be checked individually in detail.

Our rammed earth flooring is comparable in use to oiled hardwood flooring. The material does not contain any additives and is only suitable for use when sealed with wax. It can be swept, vacuumed and damp mopped; standing water should be avoided. Appropriate care should be taken to ensure unlimited durability.

For us, rammed earth is not just a product – it is a process of developing the right solution for a project with everyone involved. That’s why we accompany this process: from the initial consultation to production and acceptance. Together, we select the right services to realize the desired earth building applications with the highest quality and precision craftsmanship.